Preventing Weld Undercut Demystified: Techniques for Success

Preventing Weld Undercut Demystified: Techniques for Success

Blog Article

Understanding the Art of Welding: Just How to Prevent Undercut Welding Issues for Flawless Manufacture Outcomes

Performance and accuracy are vital on the planet of welding, where also the slightest flaw can compromise the structural honesty of a produced item. One common challenge that welders face is damaging, a defect that can lead and compromise a weld joint to pricey rework. By understanding the origin causes of undercut welding and executing effective techniques to stop it, welders can elevate their craft to new levels of excellence (Preventing weld undercut). In the pursuit of remarkable construction outcomes, understanding the art of welding to avoid undercut concerns is not just a skill yet a necessity for those pursuing excellence in their job.

Recognizing Undercut Welding

To avoid undercut welding, welders need to guarantee proper welding criteria, such as adjusting the current, voltage, travel rate, and maintaining the correct electrode angle. Furthermore, using the suitable welding strategy for the details joint arrangement is crucial. Using weaving activities or backstepping strategies can help make sure correct weld steel deposition and reduce the likelihood of undercut formation. Routine examination of welds during and after the welding process is additionally crucial to capture any type of undercut very early and make needed changes to avoid further defects. Preventing weld undercut. By comprehending the causes of undercut welding and implementing safety nets, welders can accomplish high-quality, structurally audio welds.

Sources Of Undercut in Welding

Comprehending the elements that add to damage in welding is essential for welders to create premium, structurally audio welds. When the weld metal does not correctly fill the groove formed between the base metal and the formerly deposited weld metal, undercutting happens. Numerous aspects can result in undercut in welding. One typical cause is extreme warmth input. Welding at heats for prolonged periods can lead to the base metal melting more than wanted, causing undercut. Insufficient welding inaccurate or current welding speed can additionally add to undercut. Insufficient current may not supply adequate warm to thaw the base and filler metals adequately, while too much speed can prevent appropriate fusion, triggering undercut. Additionally, inappropriate electrode angles or inaccurate torch adjustment methods can create areas of reduced weld steel deposition, advertising undercut. Understanding these causes and executing correct welding strategies can help avoid undercutting issues, making sure long lasting and solid welds.

Techniques to avoid Undercutting

To minimize the danger of undercutting in welding, welders can utilize tactical welding techniques targeted at boosting the top quality and honesty of the weld joints. One effective method is to change the welding specifications, such as voltage, existing, and take a trip speed, to guarantee proper warmth input and deposition. Preserving a suitable electrode angle and making certain regular traveling speed can also assist stop undercut. In addition, making use of the proper welding method for the specific joint arrangement, such as weave or stringer grains, can contribute to minimizing undercutting. Preventing weld undercut.

Moreover, correct joint preparation, including guaranteeing clean base materials without impurities and making use of the ideal welding consumables, is important in preventing undercut defects. Utilizing back-step welding techniques and regulating the weld bead account can additionally aid disperse warm equally and minimize the danger of undercut. Regular assessment of the weld joint during and after welding, in addition to implementing quality control actions, can assist in detecting and resolving damaging problems immediately. By carrying out these techniques diligently, welders can attain remarkable manufacture results with very little undercut flaws.

Significance of Correct Welding Parameters

Picking and maintaining suitable welding criteria is vital for attaining effective welds with marginal issues. Welding criteria refer to variables such as voltage, current, take a trip rate, electrode angle, and shielding gas circulation rate that directly influence the welding procedure. These specifications must be thoroughly changed based on the kind of product being welded, its density, and the welding method employed.

Proper welding specifications guarantee the correct amount of warmth is applied to melt the base steels and filler material evenly. If the criteria are set too expensive, it can result in extreme warm input, creating burn-through, spatter, or distortion. On the other hand, if the specifications are also reduced, insufficient combination, absence of penetration, or undercutting might occur.

Quality Control in Welding Operations

Final Thought

Finally, grasping the art of welding calls for a detailed understanding of undercut welding, its reasons, and methods to stop it. By ensuring proper welding specifications and applying quality control methods, flawless fabrication outcomes can be achieved. It is essential for welders to constantly aim for quality in their welding procedures to stay clear of undercut problems and generate high-grade welds.

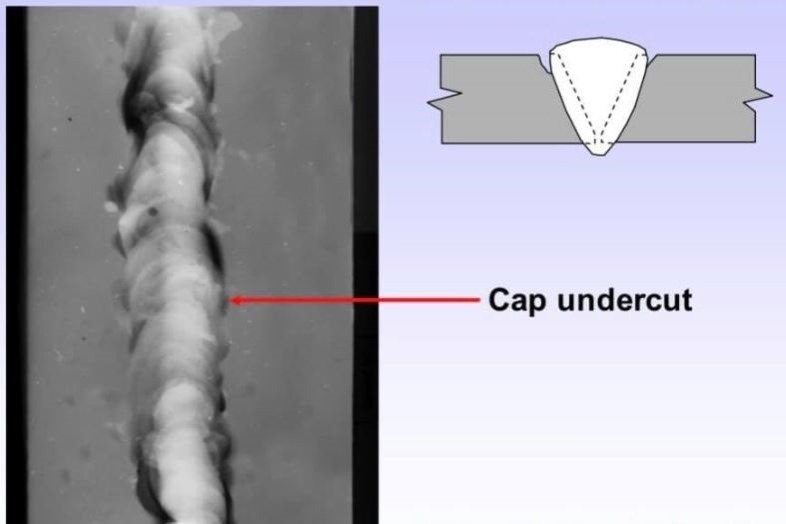

Undercut welding, a typical flaw in welding procedures, takes place when the weld steel does not properly load the groove and leaves a groove or clinical depression along the welded joint.To prevent undercut welding, welders should guarantee proper welding parameters, such as readjusting the current, voltage, traveling Learn More speed, and preserving the proper electrode angle. Insufficient welding existing or inaccurate welding speed can likewise contribute to undercut.To alleviate the risk of undercutting in welding, welders can use strategic welding methods intended at improving the quality and integrity of the weld joints.In conclusion, grasping the art of welding calls for a thorough understanding of undercut welding, its reasons, and strategies to stop it.

Report this page